- Home

- About Us

-

products

-

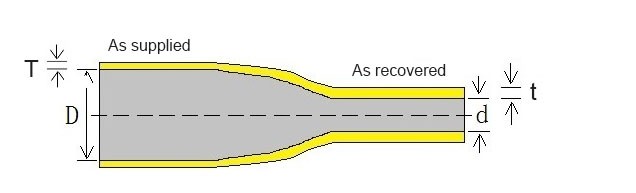

Heat Shrink Tubing

- Thin Wall Heat Shrink Tubing

- Adhesive Heat Shrinkable Tubing

- Heavy Duty Tubing

- High Temperature Heat-Shrinkable Tube

- Energy Heat Shrink Tubing

- Harnessing End Caps

- Fiber Optical Heat Shrinkable Tubing

- LED & Fluorescent Lamp Protection Sleeves

- PVC/PET Heat Shrinkable Tubing

- Pipeline Engineering Tubing/sleeves

- Heat Shrink Tubing Kit

- Luminous Tube

- Cable marker sleeve

- Insulating Tubing

- Connectors & Terminals

- Braided Sleeve

- Fire Sleeves

- Fire Fabric

- Fire Tape/Belt

- Glass fiber sleeve

- Spiral Wrap Tubing

- Wire Harness Protecting Sleeving

- 3D Printer Filament

- EVA Foam Tube

- Nylon Cable Ties

-

Heat Shrink Tubing

- Contact

.png) Contact Now

Contact Now