Product Description

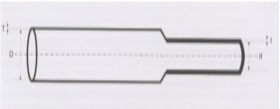

Thin Wall Flexible Plastic Tubing

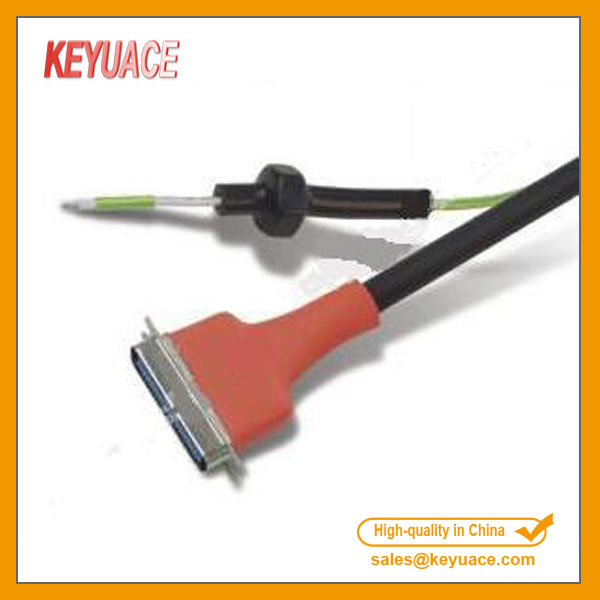

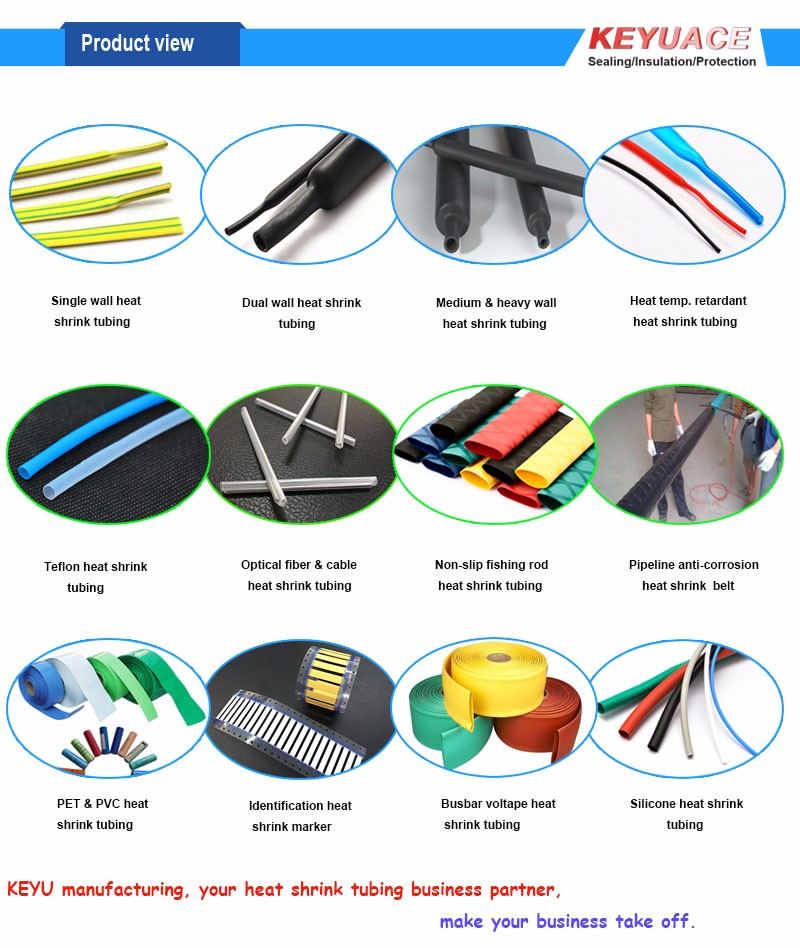

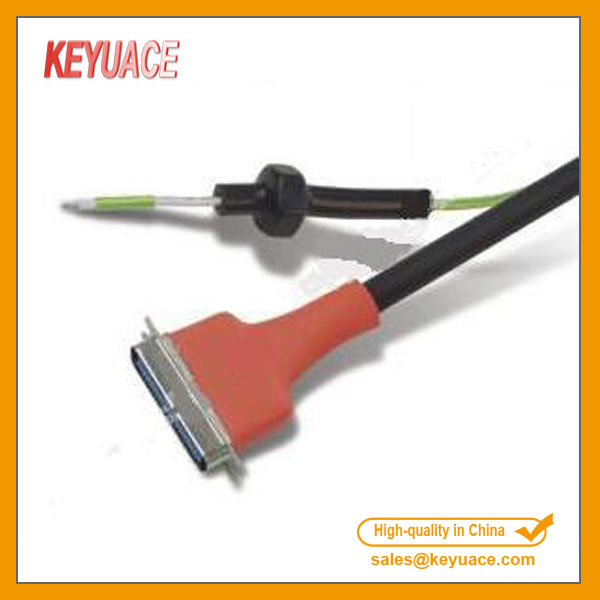

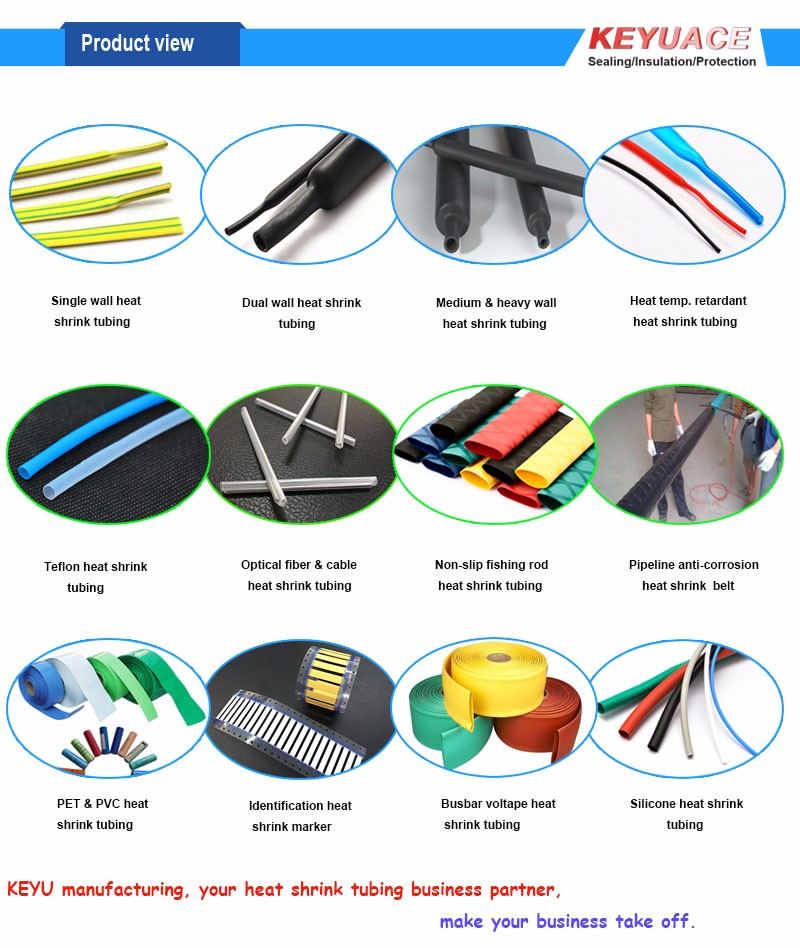

Thin Wall Heat Shrink Tubing is made of cross-linked anti 135 degrees soft PE materials. The electrical, physical, and chemical properties are very good.

Heat Shrink Polyolefin Tubing, Ultra Thin Wall Heat Shrink Tubing the main function are electric insulation of connected parts, tying-up, dust proof, identification, anti rust and corrosion, mechanical prevention. electrical heat shrinkable tube it`s widely used in electrics, communication, automotive, ship, military & aerospace sector in a variety of applications.

Flexible Polyolefin Heat Shrink Tubing, Thin Heat Resistant Shrink Tubing provides insulation, stress relief and mechanical damage and wear protection. Our white heat shrink tubing provides a high performance method for replacing standard insulation methods such as in-situ and moulded. Heat shrinkable tube has many dimensions, color and material. After heating, thermals shrink to fit the size and shape of the underlying material, accelerating and simplifying the installation process.

Thin Wall Polyolefin Heat Shrink Tubing,Waterproof Heat Shrink Tubing is very flexible and is easily marked by hot-stamp or printwheel methods.

Various

Operating temperature : -55 degrees C to +135 degrees C

Minimum shrink temperature: 83 degrees C

Minimum fully recovery temperature: 100 degrees C

Material: No PBB`s, PBBO`s, or PBBE`s. Lead content < 10 ppm.

Cadmium content < 5 ppm. RoHs compliant

Standard colors: Black, red, blue, yellow, green, white. Other colors available on request.

Shrink ratio: 2:1 (3: 1 and 4:1 available. )

Meet AMS-DTL-23053/5 & UL 224. CAN/CSA C22.2

|

Product Properties

|

Performance

requirements

|

Test method

|

Test Date

|

|

Tensile strength

|

10.4MPa min.

|

ASTM D 2671

|

≥12MPa

|

|

Elongation

|

200% min.

|

ASTM D 2671

|

≥400%

|

|

Heat shock 250℃, 4hrs

|

No cracks, no drippages

|

ASTM D 2671

|

Pass

|

|

Low temperature flexibility -55℃, 4hrs

|

No cracks

|

ASTM D 2671

|

Pass

|

|

Tensile strength after aging(175℃/168hrs)

|

70% of original min.

|

ASTM D 638

|

≥90%

|

|

Elongation after aging(175℃/168hrs)

|

100% min.

|

ASTM D 638

|

≥300%

|

|

Dielectric voltage withstand

|

2500V, 60sec, no breakdown

|

UL224

|

Pass

|

|

Dielectric strength

|

19.7KV/mm min.

|

ASTM D 2671

|

25KV/mm

|

|

Volume resistivity

|

1014Ω·cm min.

|

ASTM D 876

|

≥1014Ω·cm

|

|

corrosivity

|

No corrosion

|

ASTM D 2671

|

Pass

|

|

Flammability

|

VW-1

|

UL224

|

Pass

|

|

Size

|

As supplied (mm)

|

After recovered (mm)

|

Standard Packing

|

|

Inner diameter, D

|

Inner diameter, d

|

Wall thickness,t

|

(m/roll)

|

|

Φ1.5/0.5

|

≥1.50

|

≤0.5

|

0.45 ± 0.10

|

200

|

|

Φ3.0/1.0

|

≥3.00

|

≤1.0

|

0.55 ± 0.10

|

200

|

|

Φ4.5/1.5

|

≥4.50

|

≤1.5

|

0.60 ± 0.10

|

100

|

|

Φ6.0/2.0

|

≥6.00

|

≤2.0

|

0.65 ± 0.10

|

100

|

|

Φ9/3

|

≥9.00

|

≤3.0

|

0.75 ± 0.15

|

50

|

|

Φ12/4

|

≥12.0

|

≤4.0

|

0.75 ± 0.15

|

50

|

|

Φ15/5

|

≥15.0

|

≤5.0

|

0.80 ± 0.15

|

50

|

|

Φ18/6

|

≥18.0

|

≤6.0

|

0.85 ± 0.15

|

50

|

|

Φ24/8

|

≥24.0

|

≤8.0

|

1.00 ± 0.20

|

25

|

|

Φ30/10

|

≥30.0

|

≤10.0

|

1.15 ± 0.20

|

25

|

|

Φ39/13

|

≥39.0

|

≤13.0

|

1.50 ± 0.20

|

25

|

|

Φ50/16

|

≥50.0

|

≤16.0

|

2.50 ± 0.20

|

25

|

|

Φ60/20

|

≥60.0

|

≤20.0

|

2.60 ± 0.20

|

25

|

|

Φ70/23

|

≥70.0

|

≤23.0

|

2.60 ± 0.20

|

25

|

|

Φ80/26

|

≥80.0

|

≤26.0

|

2.60 ± 0.20

|

25

|

|

Φ90/30

|

≥90.0

|

≤30.0

|

2.60 ± 0.20

|

25

|

|

Φ100/33

|

≥100.0

|

≤33.0

|

2.60 ± 0.20

|

25

|

If you have any requirements or questions, please do not hesitate to contact me!

.png) Contact Now

Contact Now